For the last century, forklifts have been the primary equipment used in marinas for storage and retrieval. While they are the most practical solution for the majority of marina owners, forklifts present some serious concerns, such as the restricted load capacity, frequent maintenance and repairs, and high potential for damage or operator error.

In this article, you will learn how automated storage can alleviate many of the obstacles associated with forklift storage as well as some of the added benefits and opportunities created through the switch to automation.

Arguably the most important benefit of automated dry-stack storage over the traditional forklift method is the liberation of conventionally unusable space. Because of the substantial amount of space forklifts require to maneuver vessels throughout the storage facility, marina owners must sacrifice valuable cubic space that could be otherwise used for storage to accommodate this equipment.

Through the elimination of a forklift, the drive aisle is reduced by 44%. Combined with the flexibility to store multiple vessels deep and the capacity to store the heaviest vessels on the top rack, this translates to a 30-50% increase in rentable cubic space with no increase in the overall footprint.

The traditional forklift has rigid restrictions on how much weight the equipment can handle and how high that weight can be lifted. Not only does this limit the size of boats that can be stored, but also how the boats are stored.

For example, the traditional forklift is limited to storing the largest boats on the lowest racks, presents the potential for serious damage if even mid-size boats are lifted beyond the forklift’s capacity, and cannot store multiple vessels deep on the same rack.

Unlike the forklift method, the belt-driven automated storage system can safely store multiples vessels deep on one level and store even the heaviest vessels on the top rack with a height ceiling of up to 65 feet. Automation greatly reduces the potential for damage, operator error, and equipment malfunction.

Another benefit of automation over the traditional forklift method is the ability to integrate mixed-use development. The concrete tilt-wall structures that contain these automated systems can be designed to accommodate future expansion or integration of a wide range of commercial opportunities such as restaurants, shops, and greenspace. These kinds of mixed-use projects increase profitability for the marina owner, but also add value for patrons of the marina and the surrounding community.

The majority of forklift operated marinas are housed in pre-engineered metal buildings, which do not provide the same caliber of protection from storms, fire, and other environmental factors as tilt-wall concrete. Additionally, pre-engineered metal buildings are not typically designed to integrate expansion or the addition of other mixed-use developments, which could prove to be valuable sources of revenue for marina owners.

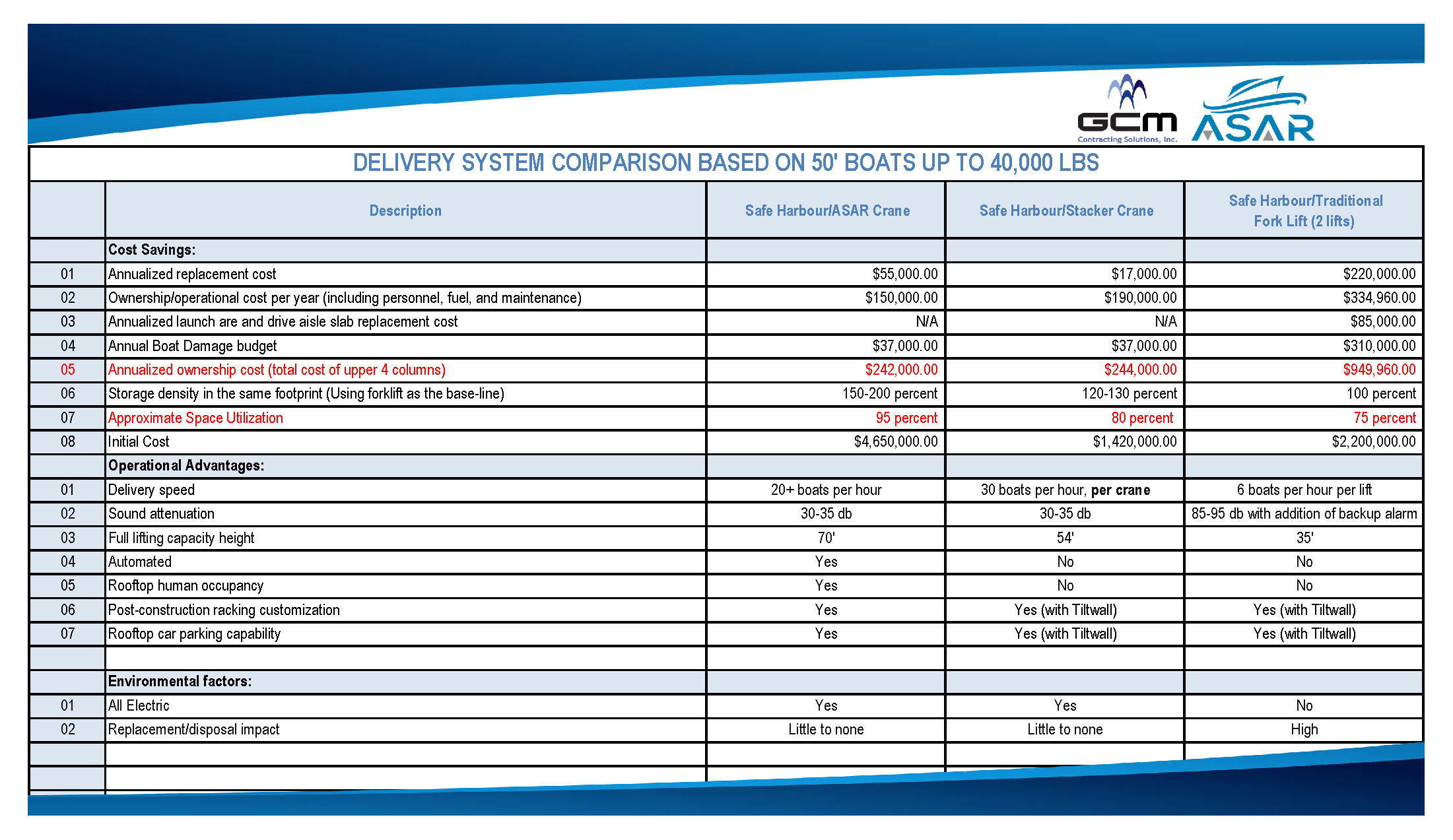

While the purchase of a forklift is typically less than half of the cost of adapting automation at a marina, the long-term costs are significantly less. Forklifts are constantly in need of maintenance, repair, and even replacement, which adds up over the years. The reliability of automated dry-stack systems significantly reduces operational, maintenance and repair costs. And while the additional safety features of tilt-wall construction increase up-front construction cost, it results in insurance premiums of up to 15% lower than a pre-engineered metal building.

While automation alleviates many of the common concerns associated with the traditional forklift method, it is not a one-size-fits-all solution. The advantages of this technology emerge in conjunction with increased land value, building height, and rentable cubic space.

A property owner who has acquired inexpensive land will most likely save money in the long run by simply choosing to build out their facility to their specifications instead of utilizing automation. Similarly, a potential client with a large plot of land may not realize all the benefits of automation because there is not necessarily a need to increase density by converting conventionally unusable space into rentable cubic space.

Another scenario where automation might not be the most profitable solution is on properties with a height restriction of three storage levels or less where a forklift remains the ideal solution. Height restrictions negate the key benefit of automated storage systems that can lift loads much higher.

Simply put, marina owners looking to increase storage density without increasing the footprint of their facility will realize the highest ROI. Those who have the available space and funds to expand via conventional means tend not to reap all of the rewards of automated dry-stack storage.

Are you a marina owner looking to create new revenue opportunities and resolve capacity issues at your marina? If so, automated dry-stack technology could be the ideal solution. To learn more about this technology and whether it’s a viable solution at your marina, contact us.